Litho Printing

Lithography, or litho printing, is one of the most widely used printing methods in the world today. It’s a process that has been around for more than two centuries, providing high-quality prints across various industries, including packaging, publishing, and promotional materials. In this article, we’ll explore the history of litho printing, the printing process, and the benefits it offers to businesses and designers alike.

Background

Lithography was invented in 1796 by Alois Senefelder, a German playwright and actor who was seeking a cost-effective way to print his scripts. Initially, he used limestone slabs and greasy crayons to create images, a method that turned out to be revolutionary.

Senefelder’s invention was based on a principle called “oil and water repelling.” He discovered that a greasy ink would adhere to certain areas of a stone plate treated with chemicals, while the untreated parts would repel ink. This process allowed him to print multiple copies from a single plate, making it a highly efficient method of reproduction.

Throughout the 19th century, lithography was used predominantly for artwork, maps, and advertising posters. Chromolithography, which introduced color printing, emerged later in the 19th century, adding another layer of versatility to the method. By the early 20th century, litho printing had evolved into offset lithography, which uses metal plates and rubber blankets instead of stone, allowing for faster and higher-quality prints. Offset litho printing is still widely in use today.

Litho Printing Process

The lithographic printing process involves several stages, utilizing the principle that oil and water do not mix. The process can vary slightly depending on the technology being used (direct lithography vs. offset lithography), but the basic steps remain the same:

Creating the Plate:

In traditional lithography, an image or text is drawn or etched onto a flat stone or metal plate using greasy substances. Modern litho printing, particularly offset lithography, uses aluminium plates coated with a light-sensitive material.

The image is exposed to the plate, and the non-image areas are treated with chemicals that attract water while repelling ink.

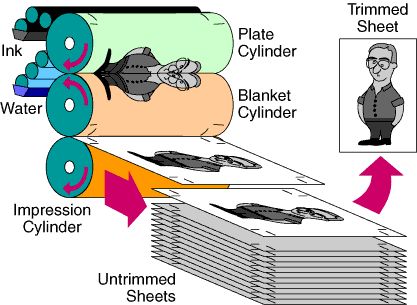

Applying Water and Ink:

During the printing process, water is applied to the non-image areas of the plate, while oil-based ink is applied to the image areas. The water repels the ink in the non-image areas, while the ink adheres to the image areas, ensuring a clean transfer.

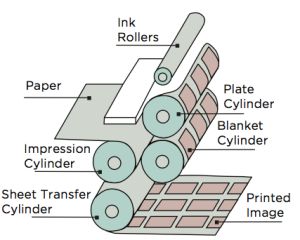

Transferring the Image:

In offset lithography, the inked image is first transferred from the plate to a rubber blanket, and then from the rubber blanket to the printing substrate (paper, cardboard, etc.). The “offset” refers to the fact that the image does not go directly from the plate to the paper, improving print quality and extending the life of the plates.

Print and Finishing: Once the ink is transferred to the paper, the final print is achieved. The paper is then dried, and additional finishing processes, such as cutting, binding, or coating, may be applied.

Benefits of Litho Printing

Litho printing offers several advantages over other printing methods, making it a popular choice for large-scale and high-quality projects. Here are some key benefits:

- Exceptional Print Quality

Litho printing produces prints with sharp, high-resolution images and text. The method is known for its precise color reproduction and detailed output, making it ideal for marketing materials, magazines, brochures, and more. - Cost-effective for Large Runs

Although the setup for litho printing can be costly due to plate creation, it becomes highly cost-effective for large print runs. Once the initial plates are made, printing hundreds or thousands of copies becomes much more economical than digital printing. - Color Consistency

Litho printing offers excellent consistency in color reproduction, which is crucial for brand consistency. The process ensures that each print is nearly identical to the others, providing reliable color accuracy across large quantities. - Wide Range of Materials

Lithography works on a variety of substrates, from paper to cardboard to plastic. This versatility allows for a broad range of applications, such as packaging, promotional materials, and labels. - Special Inks and Effects

Litho printing allows for the use of special inks, including metallic and fluorescent inks. Additionally, it supports a wide range of finishes such as gloss, matte, spot varnish, and embossing, enabling more creative and dynamic printed products. - Durable and Long-Lasting Plates

The aluminium plates used in modern lithography are durable and capable of withstanding large print runs without degrading, which reduces the need for reprints and saves costs in the long run.

Litho printing has stood the test of time, evolving from a basic stone-based method to the sophisticated, high-speed processes we use today. Its versatility, exceptional quality, and cost-effectiveness for large-scale production make it an enduring choice for businesses and designers. Whether it’s for packaging, marketing materials, or fine art prints, litho printing remains a vital technology in the world of printing.